Over 95% of GHG emissions of the logistics sector are directly attributable to handling freight for clients. So what their industry does, and how they do it, directly affects you.

In January 2023, the World Economic Forum launched a new guidance to support the logistics industry on its journey to net-zero emissions. Combined with ISO14083, there is now clarity and uniformity on how to quantify and report on GHG emissions arising from transport chain operations for passengers and freight.

The International Maritime Organization (IMO) has set an ambitious goal to reduce the shipping industry’s greenhouse gas emissions by 50% by 2050. While marine transport is recognized for having the lowest carbon emissions per ton-kilometer compared to other modes of transport, the sheer scale of global maritime freight has drawn significant attention. Fuel innovation is set to play a pivotal role in reaching these targets.

One of the most promising solutions is the adoption of fuels derived from biomass, which have the potential to reduce CO2 and sulfur emissions by as much as 90%. For example, international carriers like the Mediterranean Shipping Company (MSC) are already incorporating biofuel blends, successfully reducing their emissions by around 30%. However, the widespread use of biofuels faces a major hurdle: availability. Biofuel production currently accounts for less than 10% of the global demand for marine fuel, making it difficult to scale up usage across the entire industry.

In parallel, efforts are underway to develop liquefied natural gas (LNG) as a cleaner alternative. Companies like Qatar Petroleum and Royal Dutch Shell have partnered to advance LNG as a viable marine fuel, with Maersk adopting it for roughly 10% of its fleet. LNG offers significant reductions in both carbon emissions and other pollutants, but like biofuels, its adoption is limited by infrastructure and supply chain challenges.

On a different front, some innovators are looking to the past for inspiration. Cargill has chartered the world’s first cargo ships powered by giant wind turbines, a modern take on traditional sailing vessels. Currently, there are only about 20 large wind-powered commercial vessels in operation, but if capital costs can be reduced, the potential fuel savings and drastic reductions in emissions could lead to a resurgence in wind-powered shipping. These innovative vessels, while few in number today, could become a key player in the future of sustainable maritime transport.

Road freight, while only accounting for a quarter of marine freight by tonnage-kilometer, is over three times more polluting. Freight trucks, which contribute to around 17% of the total vehicle miles driven globally, are responsible for a staggering 39% of the life-cycle greenhouse gas (GHG) emissions of all road vehicles. This disproportionate environmental impact highlights the urgent need for reforms in the sector. According to the International Energy Agency (IEA), enhancing the fuel efficiency of diesel trucks will be crucial in curbing future diesel demand and mitigating the growth of emissions.

In India, road transport plays an even more significant role in goods movement. Nearly 75% of all goods in the country are transported via trucks, with heavy-duty trucks alone contributing to 45% of on-road emissions. This reliance on road freight positions India’s trucking industry as a critical player in the country’s transition to clean energy. As India works toward its climate goals, improving the sustainability of the road transport sector will be essential to reducing emissions, promoting energy efficiency, and supporting the nation’s broader environmental objectives.

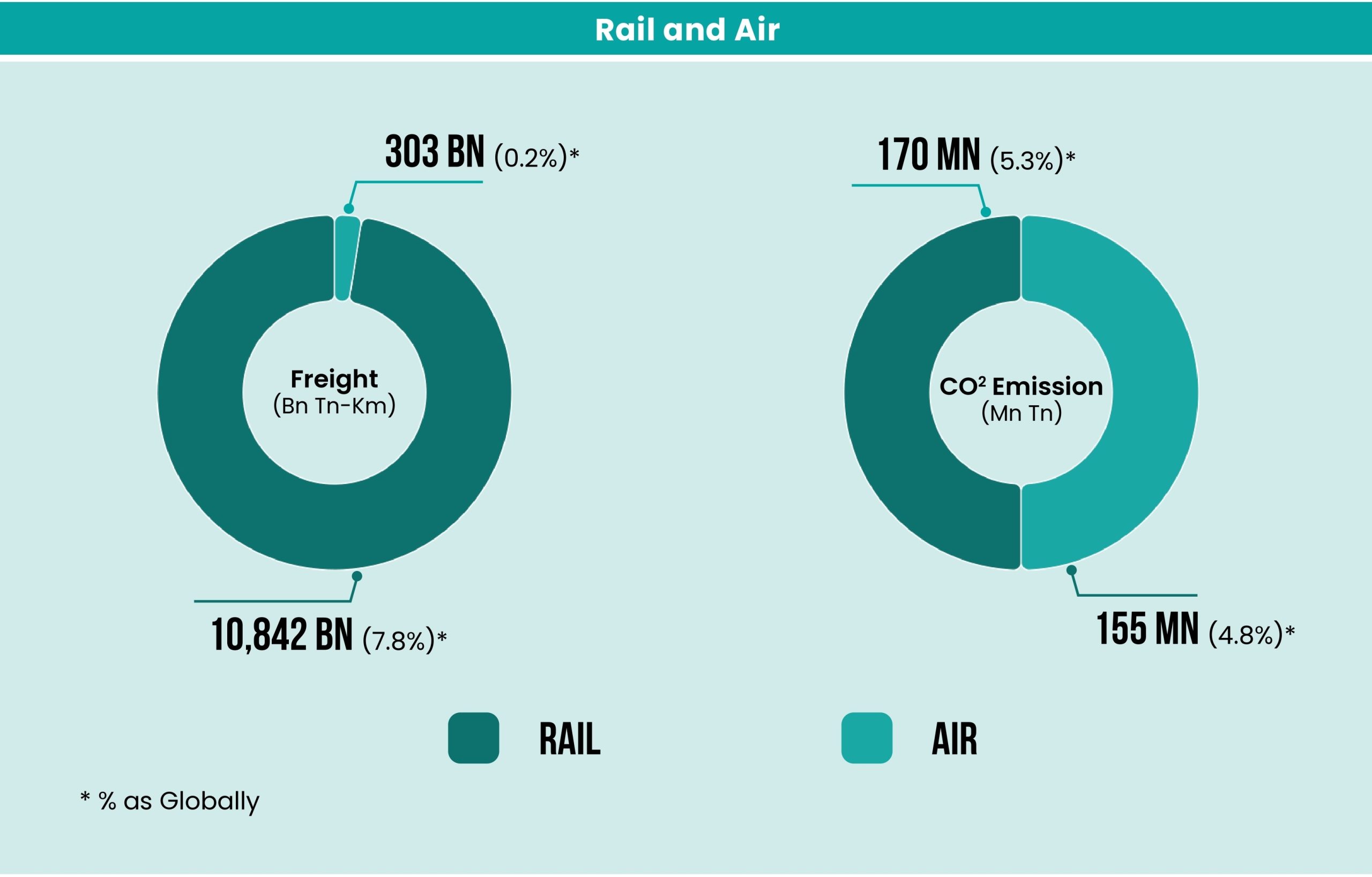

Rail transport is the most electrified transport sector. It is best placed to take advantage of the rise of renewable energy.

India plans to become the world’s first “green railway” through 100% electrification and achieving net-zero carbon emissions by 2030.

65% of the global net zero target is expected to be achieved by switching to Sustainable Aviation Fuel (SAF). India is on trend with state refineries already having conducted aircraft trials using locally produced SAF. Bharat Petroleum Corporation Limited (BPCL) plans to establish SAF facilities at its three refineries, with investments totalling Rs14bn. Private players are also focusing on green energy and ramping up SAF production. Axens and Praj have signed an MoU for joint projects to produce SAF in India. Praj GenX pilot plant is expected to be operational by 2025.

GovEVA is a leading cutting-edge digital ESG SaaS platform. Our vision is to empower large enterprises to digitize and streamline their sustainability journey, ensuring they meet their ESG goals efficiently and effectively.

+91 98202 22089

Info@goveva.com